Pipes, Tubes & Accessories

Pipes

Pipe is a hollow section with round cross section for the conveyance of fluids, gas, pellets, powders and more.

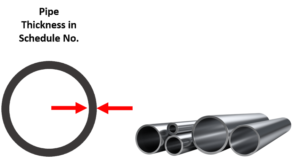

The most important dimensions for a pipe is the Outer diameter (OD) together with the Wall Thickness (WT). OD minus 2 times WT (SCHEDULE) determines the Inside Diameter (ID) of a pipe, which determines the liquid capacity of the pipe.

In Simple words, Pipe Size is determined in Nominal Bore (NB) and thickness is determined in Schedule (Sch). Comes in ERW & Seamless:

ERW or electric resistance welding pipe is manufactured using the rolling metal and then it is welded longitudinally across the length. Seamless stainless steel pipes are manufactured by extruding metal into its desired length that is why ERW pipes have welded joints in the cross-section, whereas seamless pipes do not have joints in the cross-section.

In the seamless stainless steel pipes, there is no joint or welding available and is manufactured using billet. These pipes have finished two dimensional as well as wall thickness specifications in size ranges from 1/8 inches to 26 inches OD. These seamless pipes are considered applicable for high-pressure applications.

Sizes: 3NB to 300”NB (Nominal Bore)

Pressure Class: 3Sch5, Sch10, Sch40, Sch80, Sch160, SchXX, SchXXS

Material: Stainless Steel (Gr. 304, 316, 316L)

Tubes

Tubes are as defined – they do not have a welded seam. The tubing is manufactured through an extrusion process where the tube is drawn from a solid stainless steel billet and extruded into a hollow form.

Tube has a variety of diameter, hardness, length, bore size. Seamless Tubing provides great quality, endurance and finishing.

The most important dimensions for a steel tube are the outside diameter (OD) and the wall thickness (WT). These parameters are expressed in inches or millimetres and express the true dimensional value of the hollow section.

In Simple words, Tube Size is determined by Outer Diameter (OD) in Inches/Millimetres with customizable Wall Thickness as per requirement.

At ATF, Tubes are produced to very strict tolerances. Tubular undergo several dimensional quality checks, such as straightness, roundness, wall thickness, surface, during the manufacturing process. Mechanical strength is a major concern for tubes.

Sizes: 1.5MM to 100MM (Metric); 1/16”OD to 4”OD (Imperial)

Material: Stainless Steel (Gr. 304, 316, 316L)

Tube Benders

A tube bender is a tool that bends a tube without flattening it. It is used for air conditioning and water supply piping, automotive brake pipes and mufflers, etc. It can bend tubes made of stainless steel, steel and aluminium, etc. It is compatible with tubes with large diameter and wall thickness, which are difficult to bend even with the electric type. Compatible pipe diameters, materials, bending radii, etc. differ depending on the product, so selection according to the application is necessary.

Sizes: 6MM to 25MM (Metric), 1/4”OD to 1”OD (Imperial)

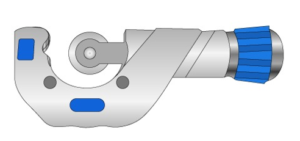

Pipe Cutter

A Pipe Cutter contains a sharp Bearing wheel blade which cuts through the pipe as it rotates, Bearing Blade helps minimize use of energy and manpower for cutting Pipes/Tubes. The wheel can penetrate further through the material the more rotations it makes. The number of rotations needed to completely cut through the pipe will depend on various influencing factors such as the material, size and thickness of the pipe, as well as the sharpness of the pipe cutter’s blade.

Sizes: 5MM to 50MM (Metric)