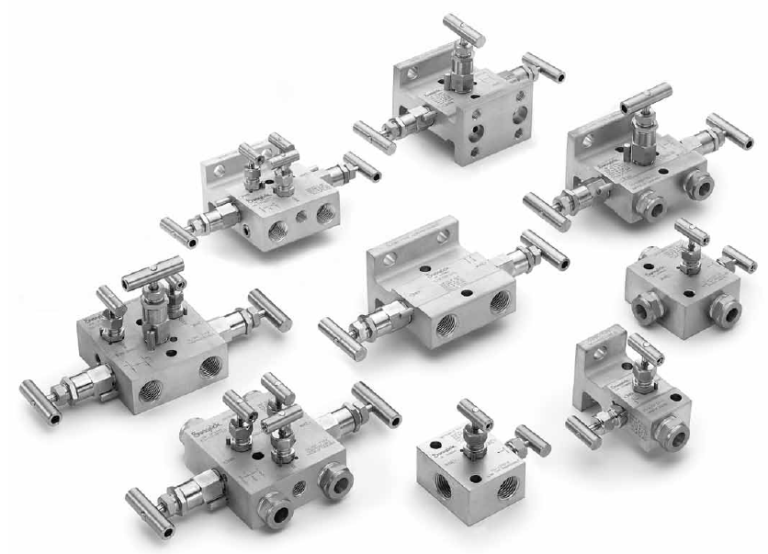

Manifold Valves

A manifold is a device that connects one or more block/isolate valves of a hydraulic system. Valves of a hydraulic system can include a ball, needle, bleed and vent valves. In the case of a block and bleed manifold, the purpose is to ensure that the fluids from upstream do not come into contact with the components from downstream. This is achieved through isolating the flow of the fluid in the system.

Manifolds are typically used with a particular number of valves based on the operation required. The most common are 2-valve, 3-valve and 5-valve assemblies.

2-valve manifolds are usually used on gauge pressure transmitters where there is a need to isolate the transmitter and vent the pressure off.

3-valve manifolds are normally used on differential pressure transmitters where it is necessary to block each process connection or equalize two sensor diaphragms.

5-valve manifolds are also used on differential setups and provide the ability to block, equalize and vent two process connections.

Valve manifolds can be useful in many situations, from small mobile machines to heavy industrial plants. Centring any fluid power system, valve manifolds improve efficiency, and reduce energy costs. Here are a few more benefits of valve manifolds:

- Increased energy efficiency with shorter flow paths that minimise pressure drop and heat.

- Reduced installation costs and fluid connections due to simpler compact design.

- Reduced oil leaks and upkeep with less connection that can fatigue, wear and loosen.

- Small and compact sizes with cartridge valve design to suit confined spaces.

- Improved overall layout with less cumbersome hoses and fluid connections.

2-Way Manifold Valves:

2-Way valve manifolds are designed for connecting system impulse line & transmitters. These Manifolds consist of two valve configuration which allows for easy isolation, calibration, block and bleed for gauges, pressure switches and static pressure transmitting instruments. These manifolds are rugged in construction to withstand high pressures and temperatures. These Manifold Valves combine the functions of a tee, calibration valve, isolation valve and all tubing and fittings into a single compact unit thus reducing number of fittings and space required for installation.

Features

- One Piece Bar stock Forged Body for high strength and fully safety.

- Bonnet lock prevents accidents disassembly.

- Stem threads rolled and hard plated provides maximum service life.

- Two Part Stem tip, stellated and hardened provides excellent flow control and ensures bubble-tight shut off.

- Ball Tip design: Which forms a bearing joint with the stem eliminates rotation between plug & seat at closure. This prevents scoring and galling up the valve seat and ensure long life in repetitive shut off service.

- Packing below stem threads prevents stem lubrication washout and isolate threads from system fluids.

- Hard seat designed to reduce packing friction giving very low torque operation.

3-Way Manifold Valves:

3-Way valve manifold is a device that is used to ensure that the capsule will not be over-ranged. It also allows isolation of the transmitter from the process loop. It consists of two block valves – high pressure and low pressure block valve – and an equalizing valve. Two block valves provide instrument isolation, and one equalize valve is positioned between the high and low transmitter process connections to provide equal pressures on both sides.

Features

- One Piece Bar stock Forged Body for high strength and fully safety.

- Bonnet lock prevents accidents disassembly.

- Stem threads rolled and hard plated provides maximum service life.

- Two Part Stem tip, stellated and hardened provides excellent flow control and ensures bubble-tight shut off.

- Ball Tip design: Which forms a bearing joint with the stem eliminates rotation between plug & seat at closure. This prevents scoring and galling up the valve seat and ensure long life in repetitive shut off service.

- Packing below stem threads prevents stem lubrication washout and isolate threads from system fluids.

- Hard seat designed to reduce packing friction giving very low torque operation.

5-Way Manifold Valves:

5-Way valve manifold is used for differential pressure transmitter. The typical 5-way valve manifold consist of 2 block valve, 1 equalizer valve, and 2 vent or test valve. If we want to check the zero of the transmitter, we just need to close the block valve and open the equalizing valve. If we want to calibrate the transmitter for 3 or 5 point calibration, then after the pressure is equalized we just need to connect the test valve to a pressure generator. This 5-way valve manifold is the most common valve manifold for differential pressure transmitter.

Features

- One Piece Bar stock Forged Body for high strength and fully safety.

- Bonnet lock prevents accidents disassembly.

- Stem threads rolled and hard plated provides maximum service life.

- Two Part Stem tip, stellated and hardened provides excellent flow control and ensures bubble-tight shut off.

- Ball Tip design: Which forms a bearing joint with the stem eliminates rotation between plug & seat at closure. This prevents scoring and galling up the valve seat and ensure long life in repetitive shut off service.

- Packing below stem threads prevents stem lubrication washout and isolate threads from system fluids.

- Hard seat designed to reduce packing friction giving very low torque operation.