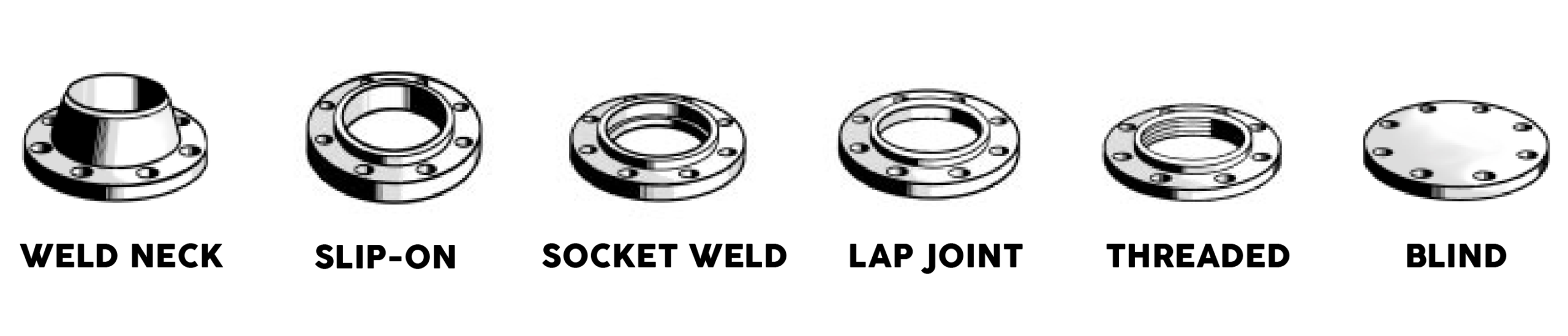

Flanges

The flange is slipped over the pipe and then welded both inside and outside to provide sufficient Strength and prevent leakage. This flange is used in preference to weld necks by many users because of its lower cost and the fact that less accuracy is required when cutting pipe to length.

A flange is a method of connecting pipes, valves, pumps and other equipment to form a piping system. It also provides easy access for cleaning, inspection or modification. Flanges are usually welded or screwed. Flanged joints are made by bolting together two flanges with a gasket between them to provide a seal.

Why choose Flanges?

• Ease of assembly in tight spaces where wrenches might not have clearance if installing traditional fittings and they are more easily assembled with moderate torque.

• Hard to reach areas where flexibility is required, eliminating the need for adapters in the tube, pipe or hose line.

• Large hose, tube or pipe connections where shock, vibration, high pressure and/or pressure surges are present, which could more easily damage a traditional large hydraulic fitting.

• Making connections that allow for easy maintenance in rigid lines such as continuous pipes or metal tubes.

• Reducing the chance of components becoming loose in rigorous Hydraulic pump.

Socket Weld Flange:

Socket weld flange simplified as SW flange, it has a recessed area (like a shoulder) in the flange bore, this shoulder serves as a guide to set the depth of the pipe that inserted to the flange. Socket welding flange initially designed for high pressure small diameters piping system. Socket weld flange could replace threaded flange, to minimize the risk of leakage. It is recommended for applications where internal welding operations are particularly difficult. This sock welded construction eliminates internal pockets while avoiding warpage of welding heat and damage to the flange face caused by weld spatter. It has the same internal pressure as the sliding on the flange, and has a better fatigue life.

Sizes: 1/2” to 4” (NB Nominal Bore)

Material: Stainless Steel (Gr. 304, 316), Monel, Inconel, Hastelloy, Duplex & Super Duplex

Slip On Flange:

Slip on flange, also called SO flange. It’s a kind of flange slides over the pipe with internal design is slightly larger than the pipe. Since the inner diameter of the flange is slightly larger than the outer diameter of the pipe, the SO flange can be directly connected to equipment or pipe by fillet weld at the top and bottom of the flange. It is used to insert the pipe into the inner hole of the flange.

Sizes: 1/2” to 4” (NB Nominal Bore)

Material: Stainless Steel (Gr. 304, 316), Monel, Inconel, Hastelloy, Duplex & Super Duplex

Lap Joint Flange:

Lap joint flange (simplified as LTF flange) shape is similar to slip on flange, it has a curved radius at the bore, which can connect with a stub end fittings and slide over the pipe. In this form, the pipe is usually welded to this stub end so the lap joint flange can rotate freely around the stub end. The advantage of this combination is that it will be easy with alignment for the bolt hole, easy to install and uninstall, much more convenient to do examinations and maintenance.

Sizes: 1/2” to 4” (NB Nominal Bore)

Material: Stainless Steel (Gr. 304, 316), Monel, Inconel, Hastelloy, Duplex & Super Duplex

Threaded Flange:

Threaded flange is connecting with pipe without welding. It is similar to slip on flange or a socket weld flange, fitted with a tapered thread (screw) inside the flange bore that is mounted on the pipe with corresponding external threads. In some cases a seal weld also applied in conjunction with threaded pipe flange. The threaded flange is screwed to the threaded pipe by the thread, which is processed in the inner hole of the flange. So it does not need to be welded and hence is so convenient for installation and maintenance.

Sizes: 1/2” to 4” (NB Nominal Bore)

Material: Stainless Steel (Gr. 304, 316), Monel, Inconel, Hastelloy, Duplex & Super Duplex

Blind Flange:

Blind flange is like a flange cover, also called blind disk or flanged pipe plug. Blind flange has no holes in the centre, for to seal the pipe opening. So its function is the same as the pipe plug or the pipe cap. The difference is blind flange is a detachable equipment, easy to replace or do maintenance. The blind flange’s the major function is totally to separate the production medium. Which preventing the shut-off valve close not tightly, then affecting production, and even causing accidents.

Sizes: 1/2” to 4” (NB Nominal Bore)

Material: Stainless Steel (Gr. 304, 316), Monel, Inconel, Hastelloy, Duplex & Super Duplex

Spectacle Blind:

Spectacle blinds (also known as Spectacle flanges) are manufactured from steel plates and are basically two interconnected discs: one is actually a ring (i.e. a disc with a hole of the same bore size of the pipeline), the other is a solid disc. In normal conditions, spectacle blinds are installed in the open position and do not interrupt the flow of the fluid conveyed by the pipeline. To blind the pipeline, and interrupt the flow, the site staff has simply to unscrew the flange bolts and rotate the spectacle blind to its closed position.

Sizes: 0-1 inch, 1-5 inch, 5-10 inch, 10-20 inch

Material: Stainless Steel (Gr. 304, 316)

Weld Neck Flange:

Weld neck flange (WN flange) has a neck that can relocate stress of the pipe, so to reduce the pressure that gathered in the flange bottom. It is compatible to the pipeline that works in high or low temperature and bear high pressure. Specially for the pipe or the valves when PN is larger than 2.5 Mpa. Welding neck flange have two forms (shapes),

• Reducing Weld Neck Flange –

• Long Neck Weld Flange –

Sizes: 1/2” to 4” (NB Nominal Bore)

Material: Stainless Steel (Gr. 304, 316), Monel, Inconel, Hastelloy, Duplex & Super Duplex